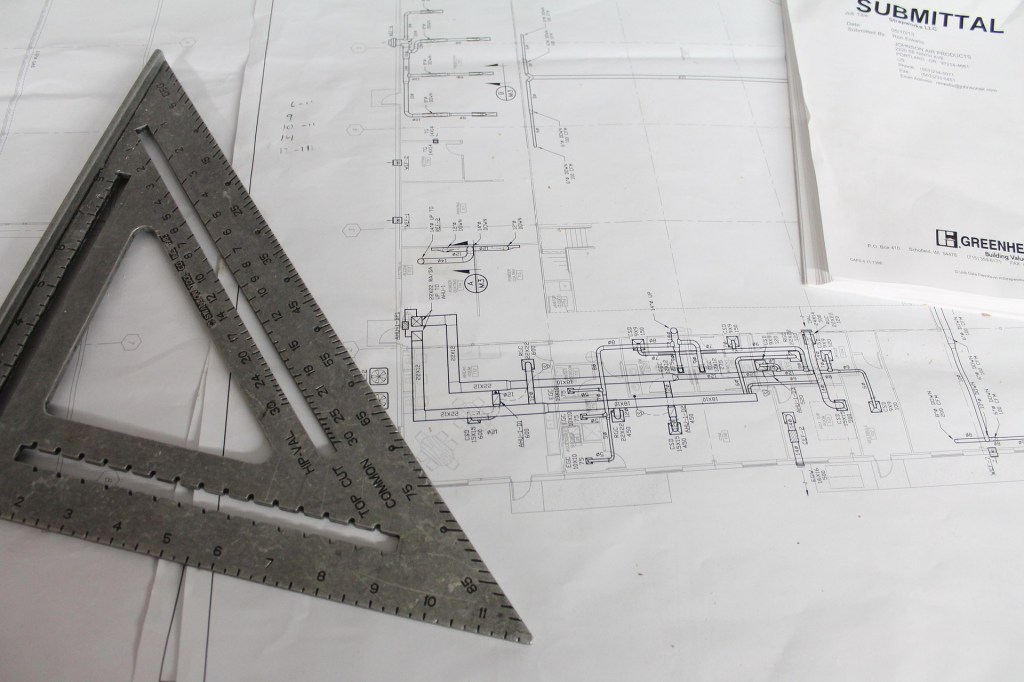

CAD drawing software has been around now for many years, actually since the early 1960s.

Primarily used to speed up design work, increase reliability and ease of sharing drawings and design ideas amongst the design team and the wider company. Revisions became much faster and more reliable, and in general the whole design process just became much quicker, accurate, reliable, and therefore commercial.

A difficulty arose though when there were many different CAD software packages in the market with different native formats. The sharing of design data between businesses therefore became a problem because one CAD file could not be loaded or edited in another program. The recipient company may have wished to manufacture a product or add the drawing/model to an engineering assembly or add building services to an architectural drawing plan but were unable to.

To overcome this problem the export of standard or generic formats was introduced so that a CAD drawing or model could be imported and/or edited within a different software. Today we have stand alone and ‘bolt on’ or ‘plug in’ translation software that can export various native files that can even preserve a high percentage of drawing history, if so desired, which is often lost in translation.

They also can export 2D & 3D PDF files that can be opened with Adobe Acrobat Reader, which is available on all devices, therefore negating the cost of buying CAD software if viewing a design or drawing is all that is required. Even so comments and ‘mark ups’ can now be added to the PDFs to facilitate design changes or suggestions.

We at Osborn Design have been providing a design & drawing service for manufacturing and building services in 2D and 3D CAD for a number of years now. CAD data file translation is key to us as we aim to serve other companies in the area of design and drawing work.

Hope you have a good month

All the best

Mike

Quotations:

” I love deadlines. I like the whooshing sound they make as they fly by.”

Douglas Adams

“Age is not a particularly interesting subject. Anyone can get old. All you have to do is live long enough.“

Groucho Marx

ps If you have enjoyed this blog please feel free to pass on to others